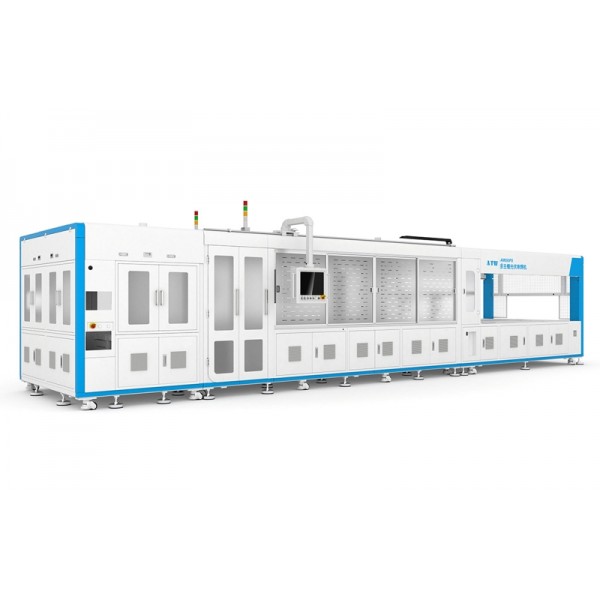

Boost Your Solar Panel Production with MBB PV Cell Soldering Stringer - Advanced Technology for Streamlined Manufacturing Processes

Type:

Specification:

Profile:

MBB PV Cell Soldering Stringer is a fully automatic machine used to non-destructively cut the mono-Si or poly-Si cells and then solder them into a string.

Boost Your Solar Panel Production with MBB PV Cell Soldering Stringer - Advanced Technology for Streamlined Manufacturing Processes

Main Function

MBB PV Cell Soldering Stringer is a fully automatic machine used to non-destructively cut the mono-Si or poly-Si cells and then solder them into a string. Normally it can work with 156-230mm (3BB-20BB) cells. The cell cut module can cut cells in half, or cut cells into three strips after upgrade. The soldering module can be upgraded for 156-230mm (full, half-cut, 1/3-cut) cells. With the use of PLC, servo, SCARA robot, industrial image processor system and other advanced automation technology, the entire process from cell feed to string outlet is fully automated.

Main Technical Parameters

|

Item |

Specifications |

Description |

||

|

Traditional Cells |

MBB Cells |

|||

|

Basic Information |

Uptime |

≥95% |

(1 - unscheduled downtime/24H), unscheduled downtime refers to the time when the equipment malfunctions or is shut down unexpectedly. |

|

|

Speed |

18Xmm cells: 3BB-12BB Half-cut≥6800 strips/hour 18Xmm cells: 13BB-20BB Half-cut≥6000 strips/hour

230mm cells: 3BB-12BB Half-cut, 1/3-cut ≥6800 strips/hour 230mm cells: 13BB-20BB Half-cut, 1/3-cut ≥6000strips/hour |

The speed depends on the solder process. If the required solder time is too long, it may affect the production speed. |

||

|

Cell Cracks |

161mm to 171mm cells: Mono-Si ≤0.2%; 171mm to 230mm cells: Mono-Si ≤0.25%; |

Popular Grade A cell, thickness ≥170μm Cell crack ratio = (cracked cells + micro-cracked cells)/total number of soldered cells × 100% |

||

|

Average Laser Power |

50W/300W |

Laser for grooving/laser for heating |

||

|

Service Life/Warranty of Laser |

Warranty: 20,000 hours |

|

||

|

Defect Detection |

CCD |

|

||

|

Overall Positioning Accuracy |

Positioning deviation: ≤±0.05mm Angular deviation: ≤±0.04° Cutting accuracy: ≤±0.1mm |

|

||

|

Groove Length |

<1.5mm |

|

||

|

Groove Depth |

0-65% (adjustable) |

|

||

|

Flux Coating Method |

Soak of ribbon |

|

||

|

Soldering Method |

IR soldering |

|

||

|

Temp Control Accuracy |

±7.5℃ |

The upper/lower temp limits can be set on HMI; an alarm will be raised when the temp is out of the limit. |

||

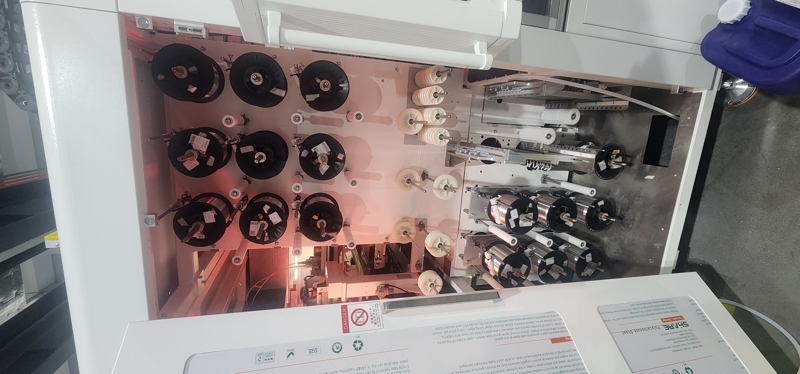

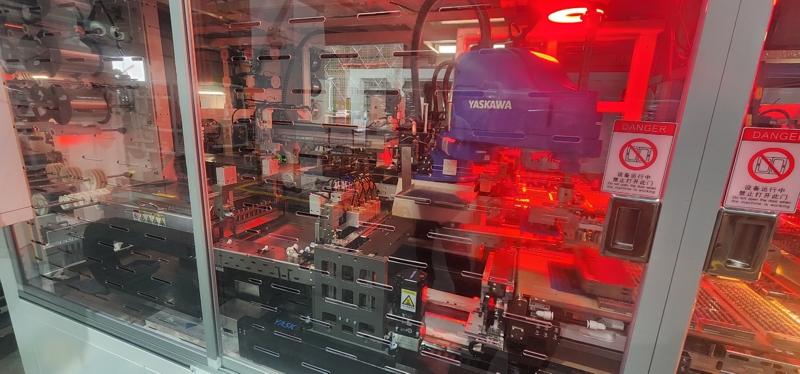

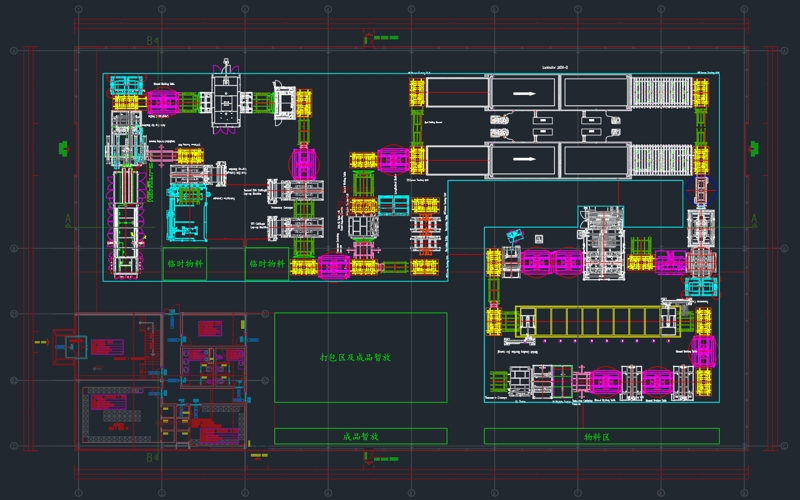

Detail picture

About US

Ooitech, One-stop solution for solar module making machine. Has the following required machinery and accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assistance, Solar Power Station installation technical support Etc.

Ooitech focus on:

Supply 10MW-500MW Solar Module Making Machine

Update the traditional PV line to newest MBB solar panel production line.

Main machinery

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

High Speed Automatic Layup Station

Customers who bought this product also purchased: